A New Approach to Creating Model Buildings

The Early Days

In the early days model railroaders built their houses and other buildings from scratch, there were no premade ready to go houses and buildings. At this stage there were not even any kits you could run down to the local hobby store and buy. You had to come up with an idea and figure out how to recreate it using whatever materials you had at hand or could pick up at your local store.

To build a house or any other building from scratch takes many hours of painstaking work. Working with a scale ruler you would first draw your building plans so that you had a starting point. Once you knew what you were building, you could start gathering the materials you needed to build it. Many of the older scratch built models were built much the same way a real house was built, one piece at a time. That meant you had to find the right sized materials and cut each individual board out by hand. Or as another option you could take a thin piece of sheet stock and using a ruler and sharp knife gently carve each board into it.

Similarly each piece of window frame and door frame had to be cut from lengths of wood, if you were building a house, this could take several hours to complete. Assembling your new house meant hours assembling small sections only to have to wait for them to dry before you could move on until the final product was assembled and ready to be painted. There were very few shortcuts and to create a model building that looked realistic was a task of many patient hours from conception to completion.

The Plastic Revolution

In the early 1950s the very first mass produced plastic model kits arrived in the stores, made by Aurora they quickly gained popularity. The model railroad industry soon joined in with easy to assemble houses and buildings. These kits featured preformed parts that made assembling buildings so much easier. By using injection molding manufacturers were able to add realistic details to every surface of the building. Walls could now be made that had each individual board or brick carefully outlined and given extra marking that could show wear and tear.

Details such as doors and windows no longer had to be built one piece at a time; many of them were molded in place while the higher quality kits came with individual doors and windows that could be glued in place. For the beginner many of these kits were molded in colors that could be used in a pinch that did not need painting, although the results were somewhat inferior to taking the time to paint each detail carefully.

The quality of these kits improved over the years as they became more popular and better manufacturing processes were used. With the advent of the computer age hobbies like this have become less popular and the number of plastic model manufacturers has declined, along with this the availability of plastic models has gone down.

Of Wood and Lasers

Modern technology catches up with everything eventually and model railroading is no different. With the advent of the computer age less people take the time to enjoy the hobby of model railroading, seems like today's youth would rather be playing games on their computers and TVs than spending hours building houses. Those that are left and still enjoy this age old hobby are becoming more demanding, plastic kits just do not give enough options for detail and customizing, so they turned to a new version of the old ways.

Laser cut wooden kits are now becoming very popular with many modelers. These high tech, high quality kits are cut out of thin sheets of materials like basswood and with work can be modified well enough to suit almost anybody. They do however come at a price; the cost of these kits can run as high as $200 or more and because of their complexity can end up sitting in the box untouched by a daunted buyer. Once you open the box you are faced with what can be several hundred individual parts that must be assembled and this can take many hours to accomplish. Some of them can take over 100 hours from start to completion and being ready to put in place on your model railroad layout.

The end result of these laser cut wooden kits can be very realistic if you have the time and patience to complete them, something that eludes many modelers. While they want the best quality models for their railroads their lives are busy and the time needed is not always available leading them to look for other methods to achieve the results they want in less time.

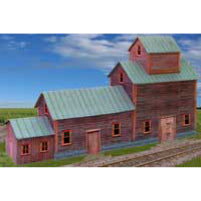

Model Builder a New Look for an Old Technique

As more modelers turn to using the high quality laser cut models they find that they are spending far more of their time working on their buildings than they are enjoying their model railroad layouts and the fun of operating them. Model builder has combined the best of the old scratch building days with new technology to make it much easier to achieve that custom built building look without having to spend countless hours gluing individual pieces together.

By using the hundreds of wall textures, doors, windows and roofing materials in Model Builder you can create buildings from scratch using nothing more than a computer, a decent quality printer and card stock. You can use the pre installed building layouts or import your own and then use the various images to create custom buildings that will enhance your model railroad layout with more detail than ever before.

If you still prefer to build your buildings using the new laser cut kits then you can use the wall and roof texture images to improve your buildings. You can use the brick prints to give you r buildings the type of finish you could only apply with hours of painstaking painting or use the wood images to give your siding a natural look. The possibilities are endless.

Model Builder features over 500 images including several different brick and block wall patterns, tin and steel siding and roofing, dozens of doors and windows and plenty of accessories to help make your buildings.

Whether you choose to make scratch built houses and buildings using Model Builder's images and card stock for a simple yet excellent building or you choose to use the printed images to help enhance your laser cut buildings you will be very surprised and satisfied with the outcome.